المركبات الخفيفة الوزن تحول عالم تصنيع الشاحنات مع فوائدها المذهلة. تعزيز الكفاءة وخفض تكاليف الوقود دعم الأهداف الصديقة للبيئة. هذه المقالة تغطس في لماذا هذه المواد تصبح الخيار الأول للأسطول الحديثة.

الخصائص الفيزيائية الرئيسية التي تجعل المركبات مثالية للتطبيقات الثقيلة

تأتي المواد المركبة مع العديد من المزايا المادية التي تناسب أجزاء جسم الشاحنة بشكل مثالي. إنها تزن أقل بكثير من الفولاذ أو الألومنيوم لكنها لا تزال تتطابق مع صلابتها وصلابتها. بالإضافة إلى ذلك ، إنهم يقفون بشكل جيد للارتداء والصدمات والاهتزازات. وهذا يجعلها مناسبة جدا للمناطق الصعبة مثل الكابينات والألواح الجانبية والسقوف. بالإضافة إلى ذلك، يمكن تشكيل المواد المركبة إلى تصاميم مفصلة أثناء الإنتاج. وهذا يسمح لأشكال أكثر سلاسة وصداقة للهواء التي ترفع الأداء العام للشاحنة.

كيف تحسن المواد الخفيفة كفاءة الوقود وقدرة التحميل

يساعد استخدام المواد المركبة الخفيفة الوزن على توفير الوقود عن طريق خفض الوزن الإجمالي للشاحنة. أقل كتلة يعني أن المحرك لا يجب أن يعمل بجد لكل ميل. وهذا يؤدي إلى انخفاض استهلاك الوقود. كما أن الأجزاء الخفيفة تعني مساحة أكبر للشحن. يمكن للأسطول نقل البضائع الإضافية دون كسر قواعد الوزن. هذا الفوز المزدوج لاستخدام الوقود بشكل أفضل ومساحة تحميل أكبر مهم للغاية للنقل لمسافات طويلة ، حيث يحسب كل بنس.

لماذا يجب أن تهتم بالفوائد الهيكلية لأجزاء الشاحنات المركبة؟

تحسين المتانة دون إضافة وزن

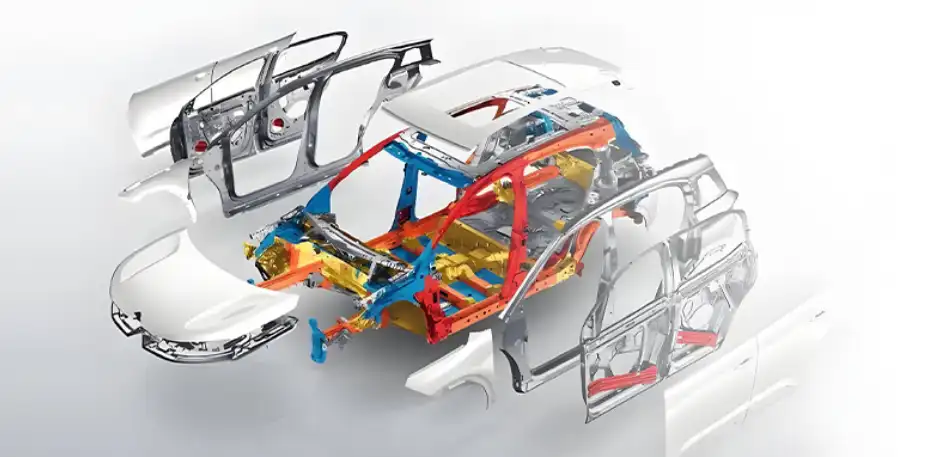

أحد المكونات الكبيرة للمواد المركبة هو صلابتها دون حجم إضافي. على عكس المعادن القديمة التي قد تنحني تحت الضغط أو الصدأ مع مرور الوقت ، تحتفظ المواد المركبة بشكلها حتى تحت ضغوط شديدة أو الطقس القاسي. وهذا يجعلها مثالية لأجزاء مثل الأعمدة A / B وإعدادات الإطار الأمامي في الشاحنات الكبيرة. نماذج المركبات المطبقة: تنطبق حاليا على نماذج مركبات فوتون ، وتستخدم لتجميع A / B – ؛ أجزاء ركيزة من جسم السيارة وهي مكون أساسي من الجبهة – هيكل إطار مقصورة القيادة ومقبرة الركاب.

مقاومة للتآكل والبيئات القاسية

المركبات تحارب بشكل طبيعي الضرر الناجم عن الماء والملح والمواد الكيميائية وأضواء الشمس - الأشياء التي تواجهها الشاحنات طوال الوقت في مناطق الطقس المختلفة. على عكس الصلب، الذي يحتاج إلى طلاء خاص لوقف الصدأ، المركبات لديها حماية مدمجة. وهذا يعني أنها تستمر لفترة أطول مع القليل من الصيانة المطلوبة.

طول العمر وتكاليف الصيانة المنخفضة مع مرور الوقت

بما أن أجزاء الشاحنات المركبة لا تتآكل أو تتعطل بسهولة من البيئة ، فهي تدوم لفترة أطول بكثير من المواد القديمة. هذا العمر الممتد يعني تبادل أقل على مر السنين. كما يقلل من فواتير الإصلاح. بالنسبة لرؤساء الأسطول الذين يبحثون عن توفير المال على مدى حياة الشاحنة الكاملة ، فهذه صفقة ضخمة.

كيف تؤثر المواد المركبة الخفيفة الوزن على السلامة والأداء؟

تحسين امتصاص طاقة الحادث وحماية الركاب

يمكن تصميم المواد المركبة لامتصاص طاقة الاصطدام بطريقة ذكية. إذا كان هناك حادث ، فإنهم ينحنون في أنماط مسيطرة على سحب التأثير بعيدا عن الناس في الداخل. وهذا يعزز سلامة الركاب. كما أنها لا تتكسر إلى قطع حادة ، مما يقلل من خطر الضرر الإضافي من القطع الطائرة.

الاستقرار في السرعات العالية وأثناء الحمولات الثقيلة

الشاحنات الخفيفة تتعامل بشكل أفضل بسرعات سريعة لأنها لديها أقل سحب. يمكن وضع الألواح المركبة في أماكن رئيسية، مثل الأسطح أو الجدران العليا، لإسقاط نقطة التوازن للشاحنة. هذا يحسن من الاستقرار عند التحول أو إجراء تحركات سريعة، حتى عندما تكون الشاحنة محملة بالكامل.

تحسين التعامل من خلال توزيع الوزن المثالي

من خلال تبادل قطع المعادن الثقيلة بخيارات أخف، يمكن للمبنين ضبط الوزن عبر إطار الشاحنة لتحقيق أفضل توازن. هذا لا يجعل الرحلة أكثر سلاسة فحسب ، بل يخفف من الإجهاد على الإطارات وأجزاء التعليق. إنها طريقة بسيطة لتحسين شعور الشاحنة على الطريق.

أين تتناسب المواد المركبة مع أهداف الاستدامة لعام 2025؟

انخفاض الانبعاثات من خلال خفض كتلة المركبة

إن خفض وزن الشاحنة هو أحد أسهل الطرق لتخفيض الانبعاثات في أسطول النقل الكبير. تحتاج السيارات الخفيفة إلى وقود أقل لكل رحلة. هذا يسقط مباشرة CO ₂ أطلق سراح لكل طن ميل مسافر. هذا رقم كبير لتتبع التقارير الخضراء.

قابلية إعادة التدوير والامتثال البيئي للمواد الحديثة

غالبا ما يتم صنع المواد المركبة اليوم لإعادة استخدامها. تقوم الشركات بإنشاء مواد مركبة على أساس البلاستيك يمكن إعادة تشكيلها أو إعادة استخدامها عندما تنتهي حياة الجزء. ولا يسمح لهم بإخراج الأشياء السيئة إلى الهواء أيضًا. هذا يتناسب مع القواعد والأهداف الخضراء العالمية.

دعم الخدمات اللوجستية الخضراء بخيارات مواد أكثر ذكاءً

لم تعد الخدمات اللوجستية الخضراء مجرد خيار. إنه أمر لا بد منه ، مدفوعًا باحتياجات العملاء والقوانين الصارمة. باستخدام أجزاء الشاحنات المركبة التي تقلل من الوزن دون فقدان القوة أو السلامة ، تظهر شركات النقل أنها تهتم بالكوكب. ومازالوا يحافظون على أرباحهم.

كيف تتكيف الشركات المصنعة مع هذه الثورة المادية؟

دمج الألواح المركبة في الكابينات والسقوف والجدران الجانبية

تصاميم شاحنات جديدة استخدم الآن الألواح المركبة في العديد من المناطق الرئيسية ، من قمم الكابينة إلى الأقسام الجانبية. هذا يساعد في كل من الوظيفة والمظهر. تقسيم أجسام السيارات إلى وحدات وظيفية مستقلة (مثل الكابينة، صندوق الشحن، الهيكل) للتجمع السريع من خلال واجهات موحدة، لتلبية الاحتياجات المخصصة لنماذج السيارات المختلفة. هذا الإعداد على غرار الكتلة يعطي الصانعين مساحة للتكيف مع الحفاظ على كل شيء قوي عبر التصاميم مثل الصناديق المموجة أو وحدات الإضافات. صندوق الشحن نوع مربع الشاحنة المموجة.

صندوق الشحن نوع المكونات – في صندوق الشاحنة.

التوافق مع خطوط الإنتاج القائمة وإمكانات التجديد

أحد الأشياء الرائعة حول التكنولوجيا المركبة اليوم هو كيفية تناسبها مع إعدادات المصنع الحالية. يمكن تشكيل الألواح أو تقطيعها بأدوات عادية. وهذا يجعلها سهلة لإضافة إلى الإنتاج المستمر أو حتى تحديث شاحنات الأسطول القديمة دون الحاجة إلى تغييرات كبيرة في الإعداد. نحن نقدم استشارات الصيانة مدى الحياة لمجموعات الهيكل الكلاسيكية وتكلفة الشحن لاستبدال الأجزاء المتوقفة (مثل ختمات الهيكل من تويوتا FJ40 1968).

كفاءة التكلفة مع مرور الوقت مقارنة بأجزاء الصلب أو الألومنيوم التقليدية

في البداية، قد تكلف المواد المركبة أكثر قليلا من المواد العادية مثل الفولاذ أو الألومنيوم. ولكن على المدى الطويل ، يوفرون المال. إنها تقلل من استهلاك الوقود ، وتستمر لفترة أطول ، ولا تتكسر من الصدأ أو التآكل في كثير من الأحيان. كل هذا يضيف إلى انخفاض التكلفة الإجمالية لملكية شاحنة.

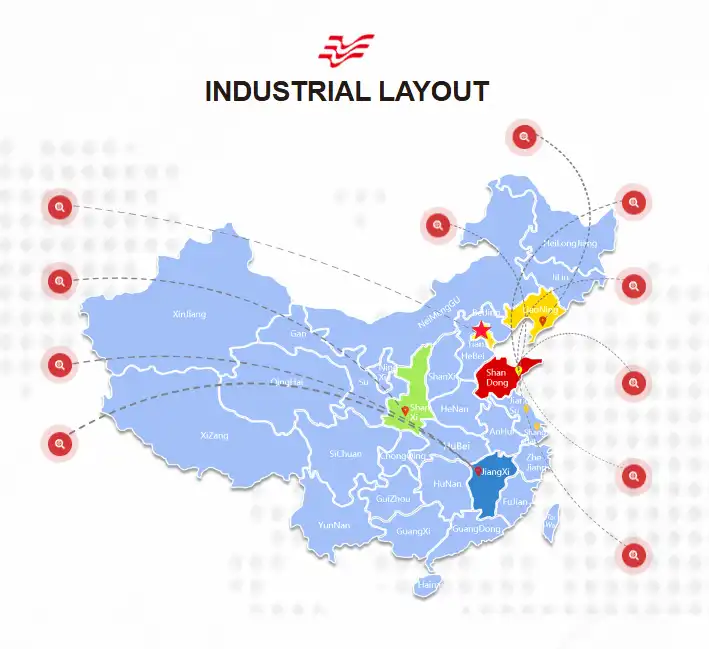

ما هو الدور الذي تلعبه تايروي في هذا التحول؟

لوحة سقف شاحنة مركبة خفيفة الوزن Tairui: ترقية ذكية للأسطول الحديثة

تظهر لوحة سقف الشاحنات المركبة الخفيفة الوزن التايروي كيف يمكن للأفكار الجديدة أن تعمل جنبا إلى جنب مع احتياجات العالم الحقيقي في تصميم النقل. صممت للعمل الصعب ولكن خفيفة بما فيه الكفاية للمساعدة في تدفق الهواء وتوفير الوقود، هذا المنتج هو طريقة سريعة لأصحاب الأسطول لزيادة الكفاءة. ولا يستسلم عن القوة أيضًا.

تايروي تجلب أكثر من مجرد المواد - إنها تجلب الإجابات. مع التركيز الحاد على الأفكار الجديدة، تم بناء أجزاء الشاحنات المركبة الخاصة بهم لتحقيق أفضل النتائج والسلامة والأهداف الخضراء. سواء كنت تحديث أسطولك أو صياغة نماذج جديدة ، فإن Tairui لديها لوحات قوية وخفيفة تقلل من استهلاك الوقود مع البقاء صعبة. وقد كسب وعدهم بالجودة الثقة بين خبراء اللوجستيات في جميع أنحاء العالم.

أسئلة متكررة

س: هل أجزاء جسم الشاحنة المركبة آمنة حقا للاستخدام؟

ج: بالتأكيد. يتم صنع المواد المركبة لاستيعاب طاقة الحادث بشكل جيد ، مما يساعد على الحفاظ على أمان الركاب في حالة وقوع حادث.

س: هل يمكنني إضافة لوحات مركبة إلى شاحناتي القديمة؟

ج: نعم، يمكنك. تعمل العديد من الألواح المركبة مع الإعدادات الحالية ، لذلك يمكن إضافتها إلى الشاحنات الموجودة دون تغييرات كبيرة.

س: هل تساعد المواد المركبة فعلا في توفير المال على المدى الطويل؟

ج: بالتأكيد. حتى لو كانت تكلف أكثر في البداية، فإن المواد المركبة توفر المال مع مرور الوقت مع أقل صيانة، واستخدام أفضل للوقود، وأجزاء أطول أمدا.