Легкие композиты преобразуют мир производства грузовиков своими невероятными преимуществами. Они повышают эффективность, снижают затраты на топливо и Поддержка экологических целейВ этой статье рассматривается, почему эти материалы становятся лучшим выбором для современных флотов.

Ключевые физические свойства, которые делают композиты идеальными для тяжелых применений

Композиты имеют множество физических преимуществ, которые идеально подходят для частей кузова грузовика. Они весят намного меньше, чем сталь или алюминий, но все же соответствуют их прочности и твердости. Кроме того, они хорошо стоят на ношение, удары и трясения. Это делает их отличным подходом для жестких мест, таких как кабины, боковые панели и крыши. Кроме того, композиты могут быть сформированы в детальные конструкции во время производства. Это позволяет получить более гладкие, воздухочистые формы, которые повышают общую производительность грузовика.

Как легкие материалы улучшают топливную эффективность и нагрузку

Использование легких композитов помогает сэкономить топливо, снижая общий вес грузовика. Меньшая масса означает, что двигатель не должен работать так сильно на каждую милю. Это приводит к снижению потребления топлива. Кроме того, более легкие детали означают больше места для груза. Флоты могут перевозить дополнительные грузы без нарушения правил веса. Эта двойная победа в лучшем использовании топлива и большем грузовом пространстве очень важна для транспорта на большие расстояния, где каждый цент считается.

Почему вы должны заботиться о конструктивных преимуществах композитных деталей грузовиков?

Повышенная долговечность без добавленного веса

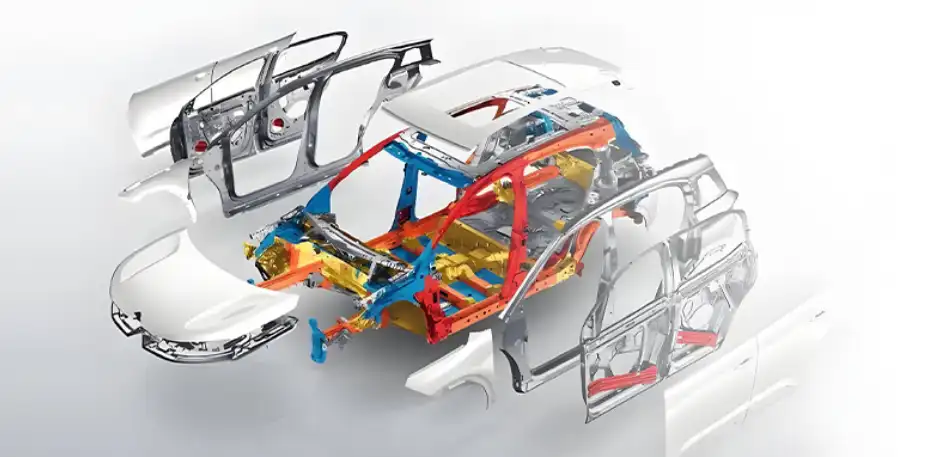

Одним из больших плюсов композитных материалов является их прочность без дополнительной массы. В отличие от старых металлов, которые со временем могут изгибаться под давлением или ржавью, композиты сохраняют свою форму даже при сильном напряжении или суровой погоде. Это делает их идеальными для таких деталей, как A / B-столбы и настройки передней рамы в больших грузовиках. Применимые модели транспортных средств: в настоящее время применяется к моделям транспортных средств Foton, он используется для сборки A / B – столбные части кузова транспортного средства и является основным компонентом передней – рамовая конструкция кабины и пассажирского отделения.

Устойчивость к коррозии и суровым условиям

Композиты естественно борются с повреждениями от воды, соли, химических веществ и солнечного света, с которыми грузовики постоянно сталкиваются в различных погодных зонах. В отличие от стали, которая нуждается в специальных покрытиях для предотвращения ржавчины, композиты имеют встроенную защиту. Это означает, что они длится дольше с небольшим содержанием.

Долговечность и снижение затрат на обслуживание со временем

Поскольку композитные детали грузовиков не износятся или легко разрушаются от окружающей среды, они прослуживают гораздо дольше, чем старые материалы. Этот продленный срок службы означает меньше обменов на протяжении многих лет. Это также снижает расходы на ремонт. Для руководителей автопарка, которые хотят сэкономить деньги на протяжении всей жизни грузовика, это огромная сделка.

Как легкие композиты влияют на безопасность и производительность?

Улучшенное поглощение энергии аварии и защита пассажиров

Композитные материалы могут быть разработаны для интеллектуального поглощения энергии столкновения. Если произойдет авария, они согнутся в контролируемых шаблонах, чтобы оттянуть удар от людей внутри. Это повышает безопасность пассажиров. Кроме того, они не ломаются на острые куски, что снижает риск дополнительного вреда от летающих кусков.

Стабильность на высоких скоростях и при тяжелых нагрузках

Легкие грузовики лучше справляются с быстрыми скоростями, поскольку они имеют меньшее сопротивление. Композитные панели могут быть размещены в ключевых местах, таких как крыши или верхние стены, чтобы снизить точку баланса грузовика. Это улучшает стабильность при повороте или быстрых движениях, даже когда грузовик полностью загружен.

Улучшенная обработка за счет оптимизированного распределения веса

Заменяя детали тяжелого металла на более легкие варианты, строители могут регулировать вес по раме грузовика для лучшего баланса. Это не только делает поездку более плавной, но и облегчает напряжение на шины и части подвески. Это простой способ улучшить чувство грузовика на дороге.

Где композиты вписываются в цели устойчивого развития на 2025 год?

Снижение выбросов за счет снижения массы транспортного средства

Сокращение веса грузовика является одним из самых простых способов снизить выбросы в крупных транспортных парках. Легкие автомобили требуют меньше топлива для каждой поездки. Это непосредственно снижает CO ₂ освобождается за тонну-милю, проехавшую. Это большое количество для отслеживания зеленых отчетов.

Переработка и экологическое соответствие современных материалов

Сегодняшние композиты часто делаются для повторного использования. Компании создают композиты на основе пластика, которые могут быть переформированы или повторно использованы, когда срок службы части заканчивается. Они тоже не пускают плохих вещей в воздух. Это соответствует глобальным зеленым правилам и целям.

Поддержка экологической логистики с помощью более умного выбора материалов

Зеленая логистика уже не просто выбор. Это обязательство, подталкиваемое как потребностями клиентов, так и строгими законами. Используя композитные детали для грузовиков, которые сокращают вес без потери силы или безопасности, транспортные компании показывают, что они заботятся о планете. И они все еще сохраняют свою прибыль.

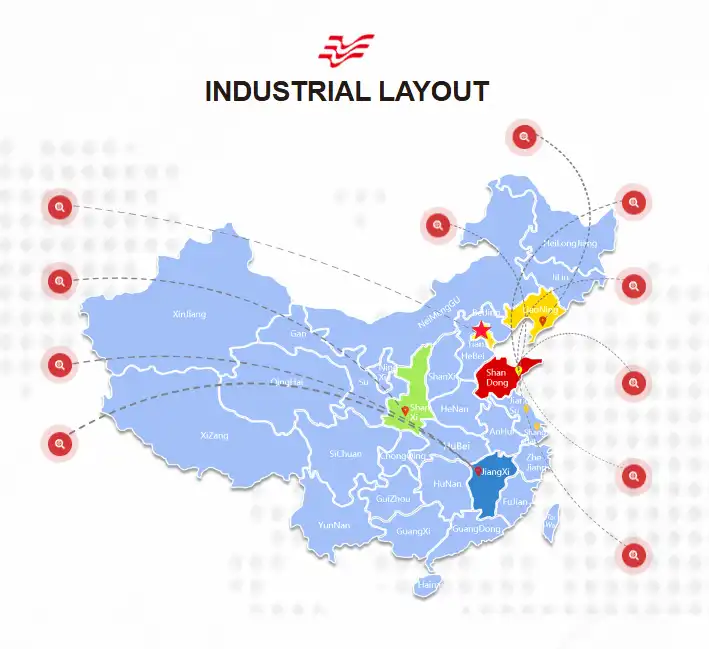

Как производители адаптируются к этой материальной революции?

Интеграция композитных панелей в кабины, крыши и боковые стены

Новые конструкции грузовиков теперь используйте композитные панели во многих ключевых областях, от вершин кабины до боковых секций. Это помогает как функциональности, так и внешности. Разделяет кузовы транспортных средств на независимые функциональные модули (например, кабину, грузовую коробку, шасси) для быстрого сочетания через стандартизированные интерфейсы, удовлетворяя индивидуальным потребностям различных моделей транспортных средств. Эта настройка в стиле блока дает производителям возможность адаптироваться, сохраняя при этом все прочное в таких конструкциях, как гофрированные коробки или плагинные блоки. Грузовая коробка типа гофрированной грузовой коробки.

Тип грузовой коробки – в грузовой коробке.

Совместимость с существующими производственными линиями и потенциал модернизации

Одна удивительная вещь о современных композитных технологиях заключается в том, как они вписываются в текущие заводские настройки. Панели могут быть оформлены или обрезаны обычными инструментами. Это делает их легкими для добавления в текущее производство или даже обновления старых грузовиков без необходимости в больших изменениях в настройке. Мы предлагаем консультации по обслуживанию на протяжении всего срока службы для классических кузовных сборок и стоимость заряда для замены прекращенных деталей (таких как уплотнения кузова Toyota FJ40 1968 года).

Эффективность затрат со временем по сравнению с обычными стальными или алюминиевыми деталями

Сначала композиты могут стоить немного больше, чем обычные материалы, такие как сталь или алюминий. Но в долгосрочной перспективе они экономят деньги. Они сокращают расход топлива, длится дольше и не разрушаются от ржавчины или износа так часто. Все это приводит к снижению общей стоимости владения грузовиком.

Какую роль играет Тайруи в этой трансформации?

Легкая композитная панель крыши грузовика TairuiУмная модернизация для современных флотов

Легкая композитная панель крыши грузовика Tairui показывает, как новые идеи могут работать рука об руку с реальными потребностями в транспортном дизайне. Сделанный для сложных работ, но достаточно легкий, чтобы помочь с потоком воздуха и сэкономить топливо, этот продукт является быстрым способом для владельцев парка для повышения эффективности. И он тоже не сдается от силы.

Тайруи Они приносят больше, чем просто материалы — они приносят ответы. Сосредоточившись на новых идеях, их композитные детали для грузовиков построены для достижения лучших результатов, безопасности и экологических целей. Независимо от того, обновляете ли вы свой парк или разрабатываете свежие модели, Tairui имеет сильные, легкие панели, которые сокращают потребление топлива, оставаясь жесткими. Их обещание качества завоевало им доверие среди экспертов по логистике по всему миру.

Часто задаваемые вопросы

В: Действительно ли композитные части кузова грузовика безопасны для использования?

А: Конечно. Композиты изготовлены для того, чтобы хорошо поглощать энергию аварии, что помогает обеспечить безопасность пассажиров в случае аварии.

В: Могу ли я добавить композитные панели к старым грузовикам?

А: Да, вы можете. Многие композитные панели работают с текущими настройками, поэтому добавление их к существующим грузовикам возможно без больших изменений.

В: Действительно ли композиты помогают сэкономить деньги в долгосрочной перспективе?

А: Конечно. Даже если они стоит больше в начале, композиты экономят деньги со временем с меньшим обслуживанием, лучшее использование топлива и более длительные детали.