คอมโพสิตน้ำหนักเบา กําลังเปลี่ยนโลกการผลิตรถบรรทุก ด้วยประโยชน์ที่น่าเชื่อ พวกเขาเพิ่มประสิทธิภาพ ลดต้นทุนเชื้อเพลิง และ สนับสนุนเป้าหมายที่เป็นมิตรกับสิ่งแวดล้อมบทความนี้ดำน้ำในวิธีการที่วัสดุเหล่านี้กลายเป็นตัวเลือกที่ดีที่สุดสําหรับเรือที่ทันสมัย

คุณสมบัติทางกายภาพหลักที่ทำให้คอมโพสิตเหมาะสำหรับการใช้งานหนัก

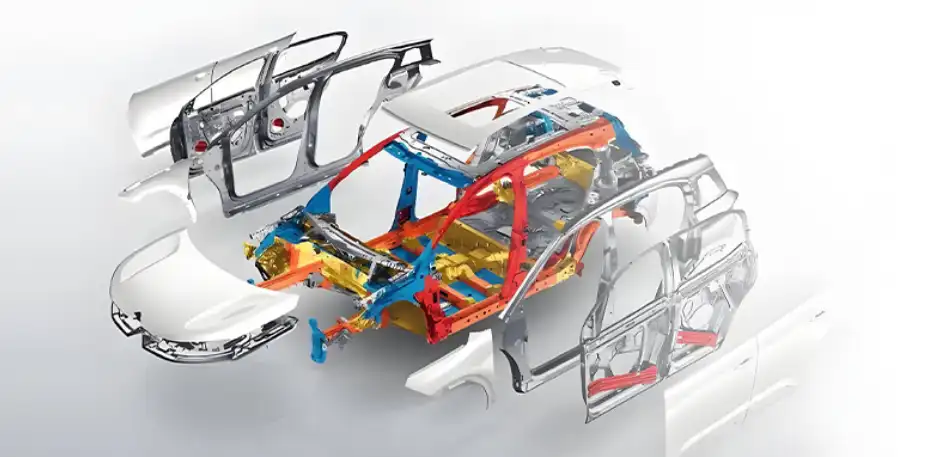

คอมโพสิตมาพร้อมกับข้อดีทางกายภาพมากมาย ที่เหมาะกับส่วนร่างกายรถบรรทุกที่สมบูรณ์แบบ มันน้ำหนักน้อยกว่าเหล็กหรืออลูมิเนียม แต่ยังคงเท่ากับความแข็งแรงและความแข็งแรงของมัน นอกจากนี้ พวกเขายืนอยู่ดีที่จะสวมใส่, กระแทก, และสั่น. นี่ทำให้พวกมันเหมาะกับจุดที่ยาก เช่น ห้องโดยสาร แผงด้านข้าง และหลังคา นอกจากนี้ คอมโพสิตยังสามารถรูปได้เป็นการออกแบบรายละเอียดในระหว่างการผลิต นี่ช่วยให้รูปร่างที่ราบรื่นและเป็นมิตรกับอากาศที่ยกประสิทธิภาพโดยรวมของรถบรรทุก

วิธีการที่วัสดุที่เบากว่าปรับปรุงประสิทธิภาพเชื้อเพลิงและความจุในการโหลด

การใช้คอมโพสิตน้ำหนักเบาช่วยประหยัดเชื้อเพลิงโดยการลดน้ำหนักรวมของรถบรรทุก น้อยกว่ามวลหมายความว่าเครื่องยนต์ไม่ต้องทำงานหนักในแต่ละไมล์ นี่นําไปสู่การใช้เชื้อเพลิงต่ำกว่า นอกจากนี้ ชิ้นส่วนที่เบากว่า หมายถึงพื้นที่มากขึ้นสำหรับสินค้า เรือสามารถขนสินค้าเพิ่มเติมได้ โดยไม่ต้องละเมิดกฎน้ำหนัก การใช้น้ำมันเชื้อเพลิงที่ดีขึ้นและพื้นที่โหลดมากขึ้นนี้เป็นสิ่งสำคัญมากสําหรับการขนส่งระยะไกล ที่ทุกเงินนับ

ทำไมคุณควรสนใจเกี่ยวกับประโยชน์โครงสร้างของชิ้นส่วนรถบรรทุกคอมโพสิต?

ความทนทานที่เพิ่มขึ้นโดยไม่เพิ่มน้ำหนัก

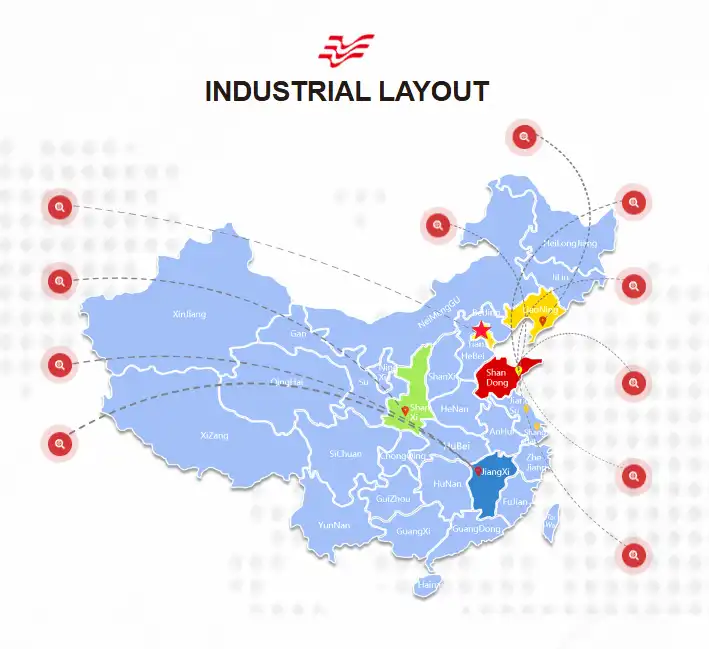

หนึ่งของวัสดุคอมโพสิตที่ใหญ่คือความแข็งแกร่งของพวกเขาโดยไม่มีจำนวนเพิ่มเติม ไม่เหมือนโลหะเก่า ที่อาจดัดภายใต้ความดันหรือสนิมในเวลาที่ผ่านมา คอมโพสิตยังคงรูปร่างของพวกเขาแม้ภายใต้ความตึงเครียดหนักหรือสภาพอากาศ นี่ทำให้พวกเขาสมบูรณ์แบบสําหรับชิ้นส่วน เช่น เสา A/B และการตั้งค่าเฟรมหน้าในรถบรรทุกใหญ่ รุ่นยานพาหนะที่ใช้ได้: ปัจจุบันใช้กับรุ่นยานพาหนะ Foton ใช้สำหรับการประกอบ A / B – ส่วนเสาของร่างกายรถยนต์และเป็นส่วนประกอบหลักของด้านหน้า – โครงสร้างกรอบของห้องนักบินและห้องโดยสาร

ความต้านทานต่อการกัดกร่อนและสภาพแวดล้อมที่รุนแรง

คอมโพสิตต่อสู้กับความเสียหายจากน้ำ เกลือ สารเคมี และแสงแดด โดยธรรมชาติ สิ่งที่รถบรรทุกเผชิญหน้าตลอดเวลาในโซนสภาพอากาศที่แตกต่างกั ไม่เหมือนเหล็กซึ่งต้องการเคลือบพิเศษเพื่อหยุดสนิม คอมโพสิตมีการป้องกันในตัว นี่หมายความว่าพวกเขาใช้งานนานกว่า โดยจําเป็นต้องบำรุงรักษาน้อย

อายุยาวนานและลดค่าใช้จ่ายในการบำรุงรักษาตามเวลา

เนื่องจากชิ้นส่วนรถบรรทุกคอมโพสิตไม่สวมใส่หรือแตกสลายได้ง่ายจากสิ่งแวดล้อม มันยาวนานมากกว่าวัสดุเก่า อายุการใช้งานที่ยาวนานี้หมายถึงการแลกเปลี่ยนน้อยลงในช่วงหลายปี มันยังลดค่าซ่อมแซม สําหรับผู้จัดการเรือที่ต้องการประหยัดเงินในชีวิตเต็มรูปแบบของรถบรรทุก นี่เป็นข้อตกลงใหญ่

คอมโพสิตน้ำหนักเบามีผลต่อความปลอดภัยและประสิทธิภาพอย่างไร?

การดูดซึมพลังงานจากการอุบัติเหตุและการป้องกันผู้โดยสารที่ดีขึ้น

วัสดุคอมโพสิตสามารถออกแบบมาเพื่อดูดซึมพลังงานการชนได้อย่างฉลาด ถ้ามีอุบัติเหตุ พวกเขาจะดัดในรูปแบบที่ควบคุม เพื่อดึงการกระแทกออกจากคนภายใน นี่เพิ่มความปลอดภัยของผู้โดยสาร นอกจากนี้ มันไม่แตกเป็นชิ้นคม ซึ่งลดความเสี่ยงของความเป็นอันตรายเพิ่มเติมจากชิ้นบิน

ความมั่นคงในความเร็วสูงและในระหว่างภาระหนัก

รถบรรทุกเบากว่าจะจัดการได้ดีขึ้นในความเร็วที่รวดเร็ว เนื่องจากมีความลากน้อยกว่า แผงคอมโพสิตสามารถวางไว้ในจุดสำคัญ เช่น หลังคาหรือผนังบน เพื่อลดจุดสมดุลของรถบรรทุก นี่จะปรับปรุงความมั่นคงเมื่อหมุนหรือเคลื่อนไหวอย่างรวดเร็ว แม้ว่ารถบรรทุกจะเต็มไปด้วย

การจัดการที่เพิ่มขึ้นด้วยการกระจายน้ำหนักที่เหมาะสม

โดยการแลกเปลี่ยนชิ้นส่วนโลหะหนักด้วยตัวเลือกที่เบา ผู้สร้างสามารถปรับน้ำหนักทั่วโครงของรถบรรทุกเพื่อความสมดุลที่ดีที่สุด นี่ไม่เพียง แต่ทําให้การขับรถเรียบง่ายขึ้น แต่ยังช่วยลดความเครียดที่ยางและชิ้นส่วนระงับ มันเป็นวิธีง่ายที่จะปรับปรุงความรู้สึกของรถบรรทุกบนถนน

คอมโพสิตจะเข้ากับเป้าหมายความยั่งยืนในปี 2025 ได้อย่างไร?

การปล่อยก๊าซลดลงผ่านการลดมวลยานพาหนะ

การลดน้ำหนักของรถบรรทุกเป็นหนึ่งในวิธีที่ง่ายที่สุดในการลดการปล่อยในรถขนส่งใหญ่ ยานพาหนะเบากว่า ต้องใช้น้ำมันน้อยกว่าสําหรับการเดินทางแต่ละครั้ง นี่ทำให้ CO ลดลงโดยตรง ₂ ปล่อยต่อตอนไมล์ที่เดินทาง นั่นเป็นจำนวนมากที่จะติดตามรายงานสีเขียว

การรีไซเคิลและความเป็นไปตามสิ่งแวดล้อมของวัสดุที่ทันสมัย

คอมโพสิตในปัจจุบันมักจะถูกสร้างเพื่อใช้ใหม่ บริษัทกําลังสร้างคอมโพสิตที่ใช้พลาสติก ที่สามารถปรับปรุงหรือใช้ใหม่ได้เมื่ออายุการใช้งานของชิ้นส่วนสิ้นสุด พวกเขาไม่ปล่อยสิ่งที่ไม่ดีออกไปในอากาศด้วย นี่เหมาะกับกฎและเป้าหมายสีเขียวทั่วโลก

การสนับสนุนโลจิสติกสีเขียวด้วยการเลือกวัสดุที่ฉลาดกว่า

โลจิสติกสีเขียวไม่ใช่แค่ทางเลือกอีกต่อไป มันเป็นสิ่งที่ต้องดันจากทั้งความต้องการของลูกค้าและกฎหมายที่เข้มงวด โดยใช้ชิ้นส่วนรถบรรทุกประกอบที่ตัดน้ำหนักโดยไม่สูญเสียความแข็งแรงหรือความปลอดภัย บริษัทขนส่งแสดงให้เห็นว่าพวกเขาสนใจโลก และพวกเขายังคงทำกำไรให้สูงขึ้น

ผู้ผลิตปรับตัวต่อการปฏิวัติวัสดุนี้อย่างไร?

การรวมแผงคอมโพสิตในห้องโดยสาร หลังคา และผนังด้านข้าง

การออกแบบรถบรรทุกใหม่ ตอนนี้ใช้แผงคอมโพสิตในหลายพื้นที่สำคัญ ตั้งแต่ด้านบนของห้องโดยสารจนถึงส่วนด้านข้าง นี่ช่วยทั้งการทํางานและรูปลักษณ์ แบ่งร่างกายรถเป็นโมดูลการทํางานที่อิสระ (เช่น แคบี้, กล่องสินค้า, แชสซี่) เพื่อการรวมอย่างรวดเร็วผ่านอินเตอร์เฟซมาตรฐาน, ตอบสนองความต้องการ การตั้งค่ารูปแบบบล็อกนี้ให้ผู้ผลิตมีพื้นที่ในการปรับตัว ขณะที่รักษาทุกอย่างที่แข็งแกร่งในการออกแบบ เช่นกล่องลูกฟูกหรือหน่วยปลั๊กอ กล่องบรรทุกชนิดลูกฟูก

กล่องสินค้าประเภทปลั๊ก – ในกล่องรถบรรทุก

ความเข้ากันได้กับสายการผลิตที่มีอยู่และศักยภาพในการปรับปรุง

สิ่งที่น่าทึ่งเกี่ยวกับเทคโนโลยีคอมโพสิตในปัจจุบันคือวิธีการที่มันเหมาะกับการตั้งค่าโรงงานในปัจจุบัน แผงสามารถรูปร่างหรือตัดได้ด้วยเครื่องมือปกติ นี่ทำให้พวกเขาง่ายต่อการเพิ่มเข้าสู่การผลิตที่ต่อเนื่อง หรือแม้กระทั่งอัพเดทรถบรรทุกเก่า โดยไม่ต้องมีการเปลี่ยนแปลงใหญ่ในการตั้งค่ เราให้คำปรึกษาด้านการบำรุงรักษาตลอดอายุการใช้งานสําหรับการประกอบระบบคลาสสิกและค่าใช้จ่ายในการเปลี่ยนชิ้นส่วนที่หยุดใช้ (เช่น ซีลร่างกายของ Toyota FJ40

ประสิทธิภาพต้นทุนในเวลาเทียบกับชิ้นส่วนเหล็กหรืออลูมิเนียมทั่วไป

ตอนแรก คอมโพสิตอาจมีราคามากกว่าวัสดุปกติ เช่นเหล็กหรืออลูมิเนียม แต่ในระยะยาว พวกเขาประหยัดเงินสด พวกเขาลดการใช้เชื้อเพลิง ใช้งานนานกว่า และไม่แตกจากสนิมหรือสวมใส่บ่อยเท่านั้น ทั้งหมดนี้เพิ่มค่าใช้จ่ายรวมที่ต่ำกว่า ในการเป็นเจ้าของรถบรรทุก

Tairui มีบทบาทอะไรในการเปลี่ยนแปลงนี้?

แผงหลังคารถบรรทุกคอมโพสิตน้ำหนักเบาของ Tairuiอัพเกรดที่สมาร์ทสำหรับเรือที่ทันสมัย

แผงหลังคารถบรรทุกคอมโพสิตน้ำหนักเบาของ Tairui แสดงให้เห็นว่าความคิดใหม่สามารถทำงานร่วมกับความต้องการของโลกจริงในการออกแบบการขนส่งได้อย่างไร ผลิตภัณฑ์นี้ถูกสร้างขึ้นสำหรับงานที่ยาก แต่เบาพอที่จะช่วยในการไหลของอากาศและประหยัดเชื้อเพลิง ผลิตภัณฑ์นี้เป็นวิธีที่รวดเร็วสําหรับเจ และมันก็ไม่ยอมแพ้ความแข็งแรง

ไทรุย นํามากกว่าเพียงวัสดุ พวกเขานําคำตอบ ด้วยการเน้นความคิดใหม่ ชิ้นส่วนรถบรรทุกคอมโพสิตของพวกเขาถูกสร้างขึ้นเพื่อผลลัพธ์ที่สูงสุด ความปลอดภัย และเป้าหมายสีเขียว ไม่ว่าคุณจะปรับปรุงเรือของคุณหรือการสร้างรุ่นสด Tairui มีแข็งแรง, แผงเบาที่ลดการใช้เชื้อเพลิงในขณะที่ยังคงยาก. ความมั่นใจของพวกเขาเกี่ยวกับคุณภาพได้ทำให้พวกเขามีความไว้วางใจในหมู่ผู้เชี่ยวชาญด้านโลจิสติกส์ทั่วโลก

คำถามที่พบบ่อย

Q: ชิ้นส่วนร่างกายรถบรรทุกคอมโพสิตปลอดภัยจริงๆหรือไม่?

ตอบ: แน่นอน คอมโพสิตถูกสร้างเพื่อใช้พลังงานในการอุบัติเหตุได้ดี ซึ่งช่วยให้ผู้โดยสารปลอดภัยถ้ามีอุบัติเหตุ

Q: ฉันสามารถเพิ่มแผงคอมโพสิตให้กับรถบรรทุกเก่าของฉันได้หรือไม่?

ตอบ: ใช่คุณสามารถ แผงคอมโพสิตหลายแผงทํางานกับการตั้งค่าปัจจุบัน ดังนั้นการเพิ่มมันในรถบรรทุกที่มีอยู่เป็นไปได้โดยไม่มีการเปลี่ยนแปลงใหญ

Q: คอมโพสิตช่วยประหยัดเงินในระยะยาวจริงหรือไม่?

ตอบ: แน่นอน แม้ว่าจะมีค่าใช้จ่ายมากขึ้นในเริ่มต้น คอมโพสิตจะประหยัดเงินในช่วงเวลา ด้วยการบำรุงรักษาน้อยกว่า การใช้เชื้อเพลิงที่ดีกว่