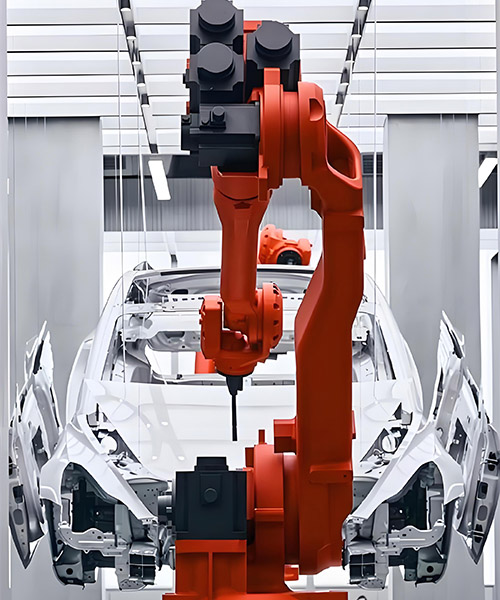

We build a vertical technology ecology from basic material research and development to vehicle system integration, focusing on breakthroughs in the field of metal parts and multi-material composite connection technologies, forming a full-stack research and development capability covering new energy vehicle architecture, intelligent special vehicle platform, and high-performance subsystems. Relying on reliable and accurate product and process equipment technology, the core competitiveness of technology and cost is formed, and the diversified needs of customers in the automotive industry are continuously met.

Engineering Research and development staff

Research and Development Center

At present, there are two departments: Vehicle Research Institute and special Vehicle Research Institute. With more than 100 professional and technical personnel, it has a complete production line of stamping, welding, assembly and painting. With an annual output of 20,000 vehicles, 10,000 special vehicles design and manufacturing capabilities.

In vehicle research and development, we deeply investigate the needs, use digital simulation technology to design the architecture, through the wind tunnel, durability test, taking into account power, safety, comfort, and create a sense of science and technology and aesthetic appearance. In terms of special vehicles, whether it is municipal sanitation, emergency vehicles, or logistics refrigeration, van, we can accurately meet the needs of the industry, adopt modular design, flexible configuration of professional equipment, to provide customers with one-stop vehicle solutions, leading the development of the industry.

Based on professional design, the technical team starts from customer requirement, tailors products to meet customer requirement with integrated design advantages, and has perfect system integration design from demand to realization.

Body R & D center has more than 80 professional and technical personnel, with a complete design and development process, collaborative development ability, performance experiment and CAE analysis, AutoForm process analysis, mold DL diagram design and structure diagram design capabilities.We have rich industry experience in the stamping process of body products. It has more than 100 national patents on stamping, welding invention and utility model.

We have excellent customization and standardization design capabilities. We can accurately focus on the individual requirement of customers, and carry out exclusive body customization design for various models. At the same time, we strictly follow the international authority for standardized design,and provide our customers with car bodies that meet both individual requirement and international quality certification.

We focus on the research of new automotive materials. Under the premise of ensuring the strength and safety performance of the body, we deeply study the influence of heat treatment and molding process on the performance of the final parts, compare the deformation performance of different materials, optimize the existing automotive material system, create a new generation of high-strength and tough materials, and promote the lightweight of automobiles with professional programs.

We have a highly skilled, united and cooperative high-quality technical team, with a number of automotive lights in the field of patented technology. We have complete and independent forward design, reverse design and synchronous design and development capabilities, it focuses on the optimization of automotive lighting drive technology, the advancement of ADB intelligent lighting system, and the innovative research and development of DLP intelligent lighting solutions.

We have a complete automotive headlight independent research and development system, including product structure design and development, electronic design and development, tooling mold design and development, cutting-edge technology development. From conceptual design and structural design to module development and visual scheme, we have realized optical and electric integration and electronic self-research. Relying on mold construction, process optimization and intelligent manufacturing, the whole process is accurate to create high-quality lights.

Relying on professional optical design team and cutting-edge technology concept, we can carry out the optical design of automotive interior and exterior decoration lamps. While adhering to SAE, ECE, CCC and other international standards, we are incorporating innovative elements to meet customers' ultimate pursuit of safety, beauty and innovation.